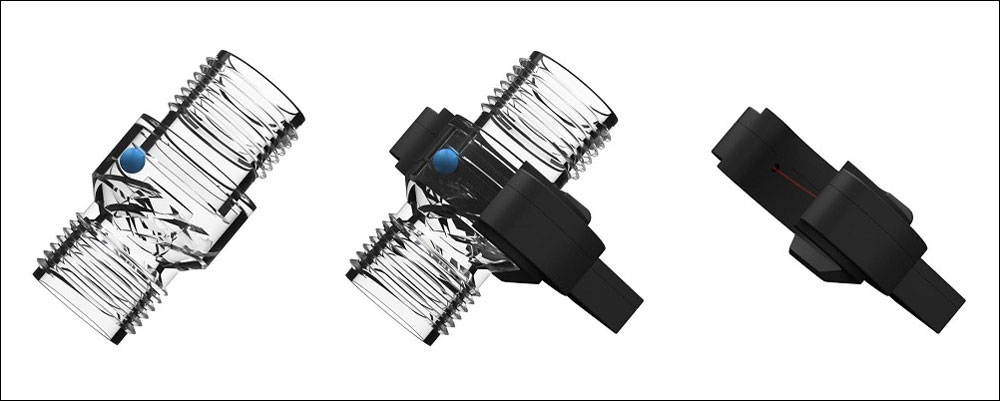

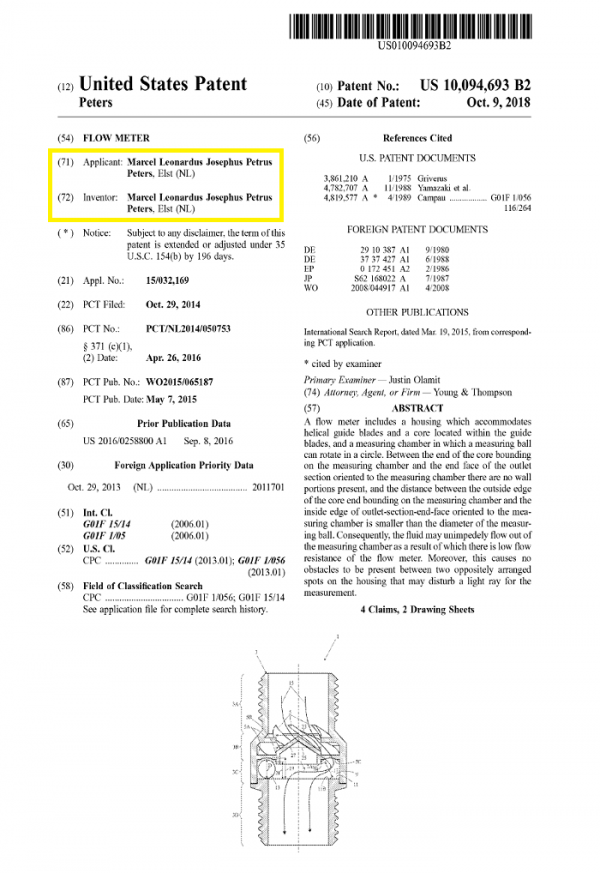

WO2015065187 (A1) 2015-05-07 Inventor MLJP Peters

Uploading a video of this flow meter on ![]() suddenly generated a lot of interest in this innovation. Because of this video, I received a lot of response from interested companies around the world. Companies I could never have reached otherwise. Judging by the many applications, there appears to be a high demand for a flow meter with these renewed properties.

suddenly generated a lot of interest in this innovation. Because of this video, I received a lot of response from interested companies around the world. Companies I could never have reached otherwise. Judging by the many applications, there appears to be a high demand for a flow meter with these renewed properties.

The many comments on YouTube prompted me to develop and improve the second version by making new adjustments. One of the big differences is that the 3rd version flow meter does not have a cage construction.