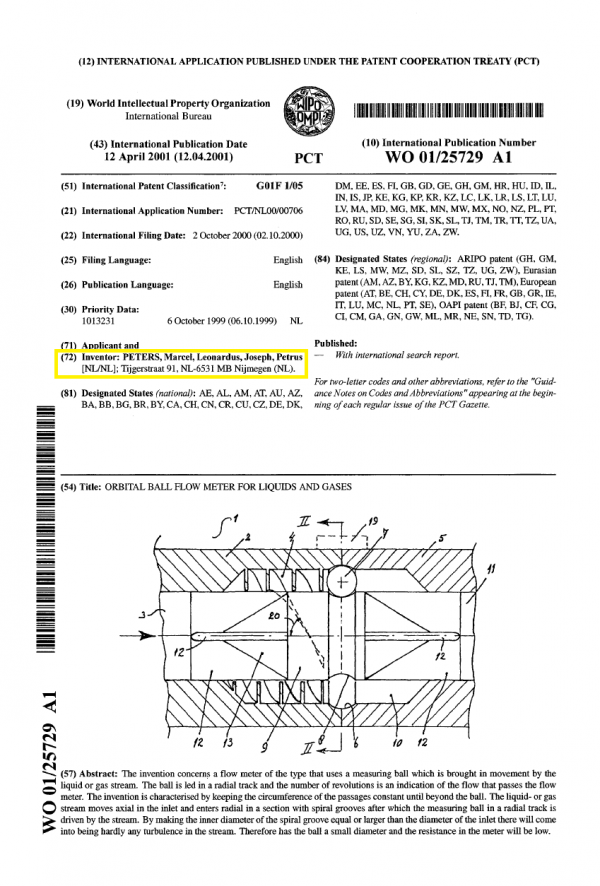

3 revolutionair nieuw ontwikkelde flowmeters

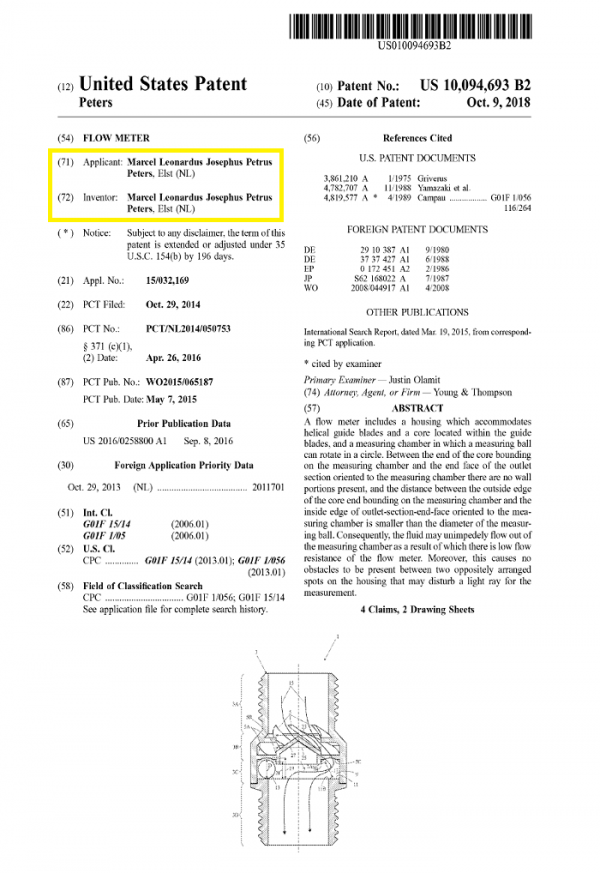

Nieuw: De 4e generatie flowmeter – Een revolutie in vloeistofmeting

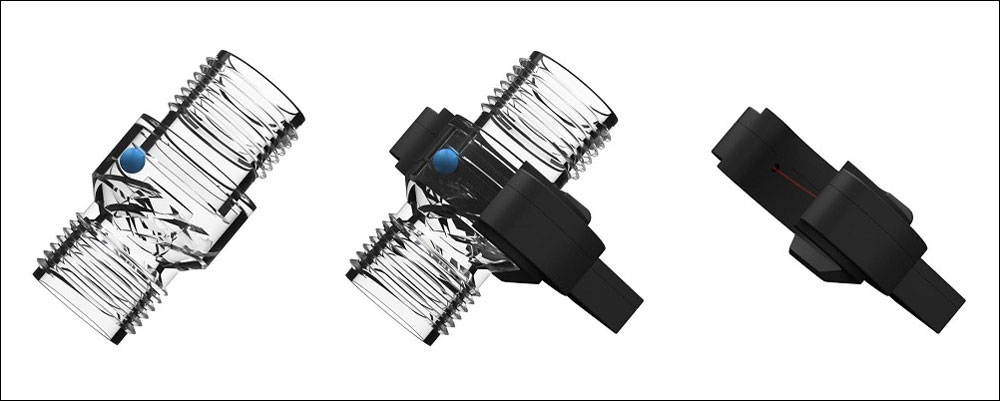

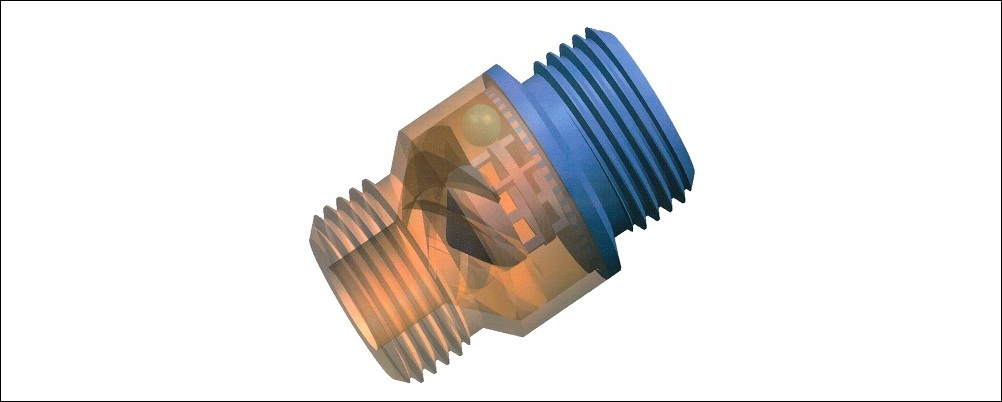

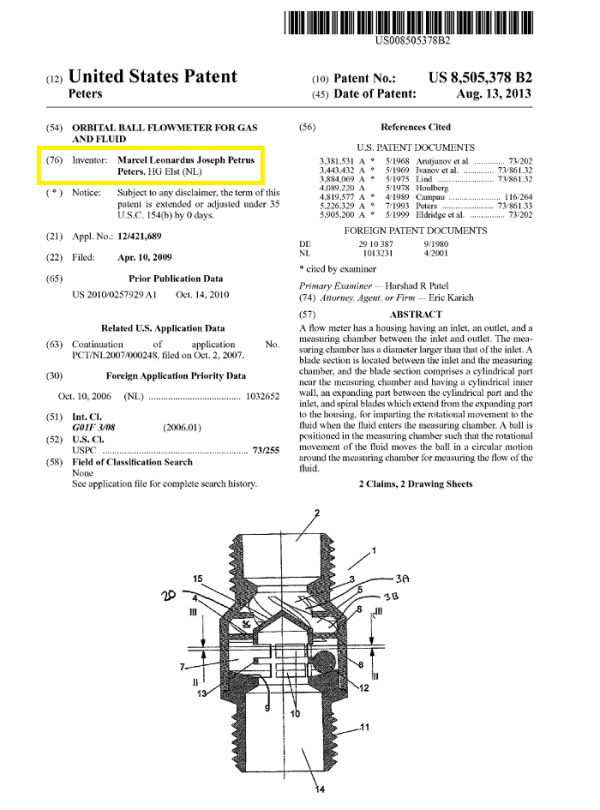

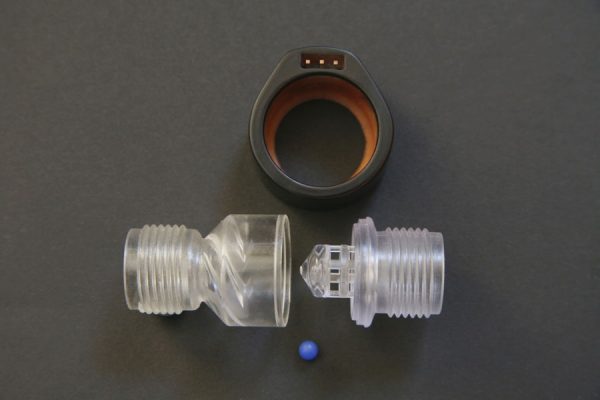

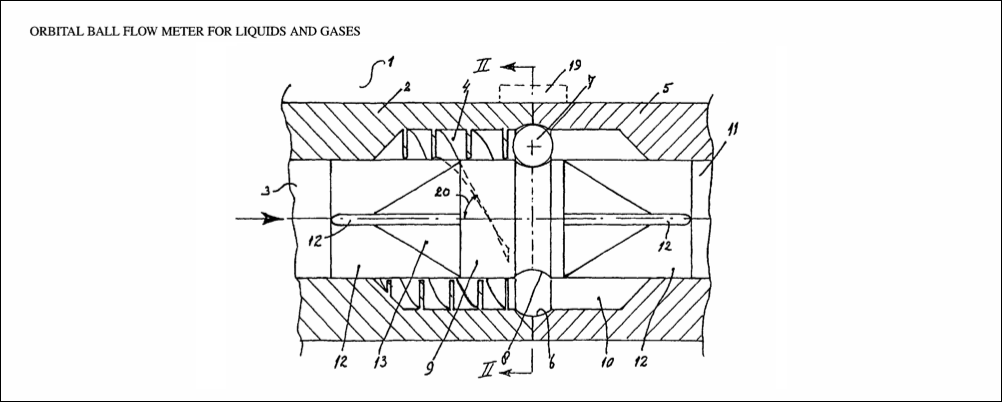

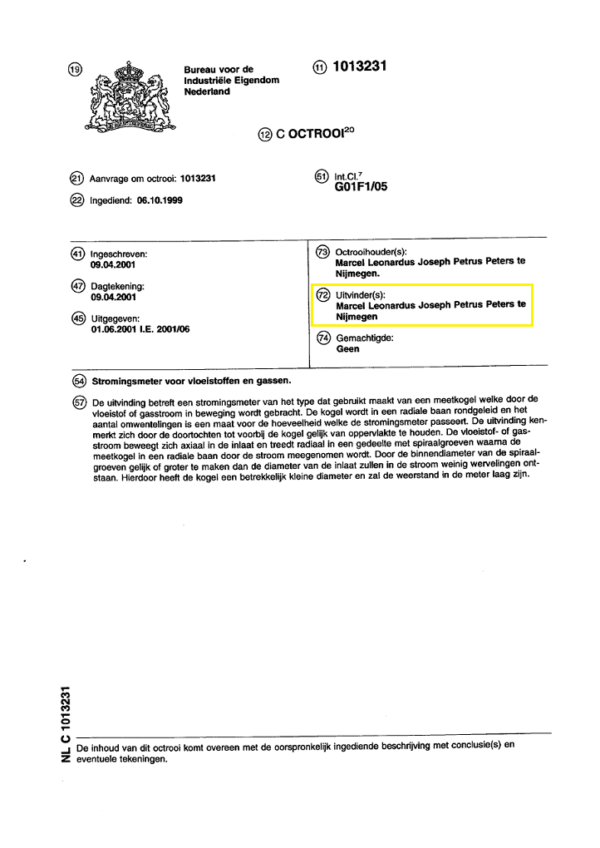

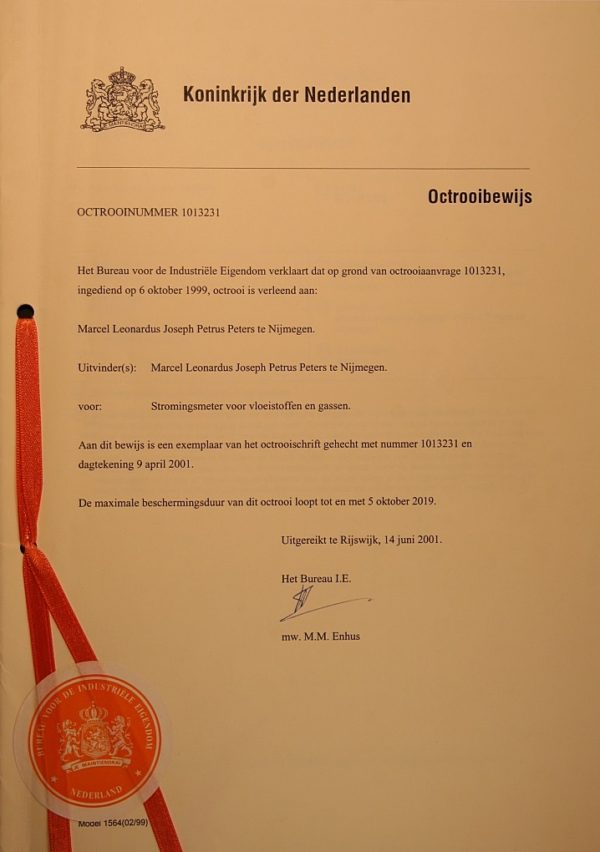

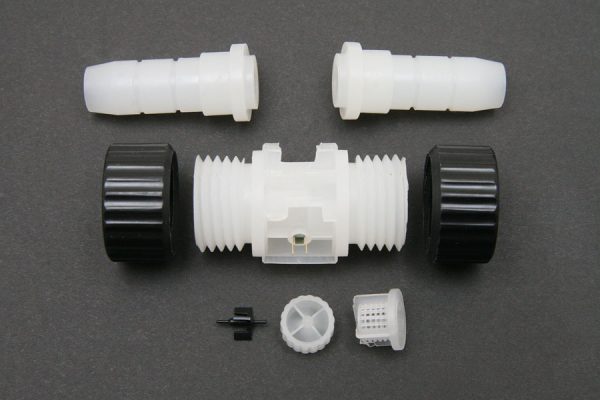

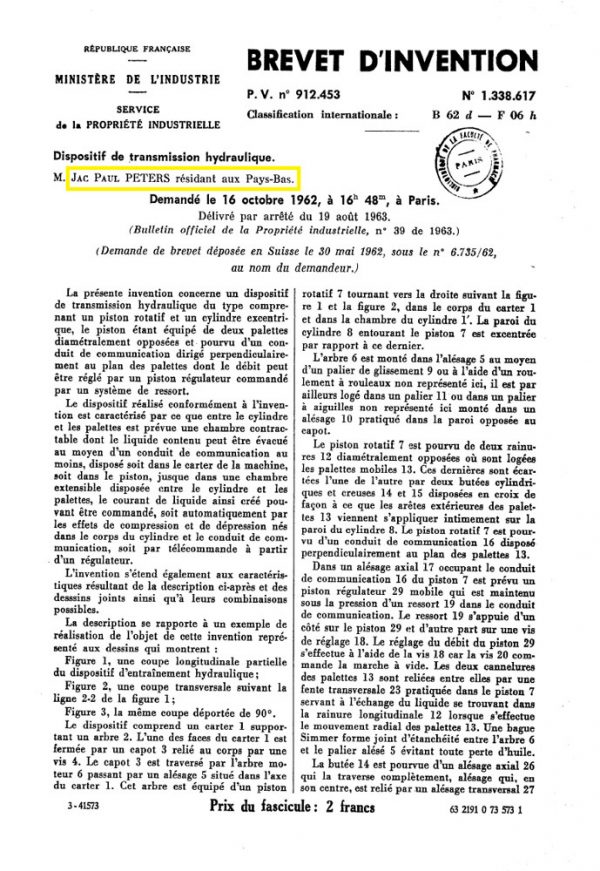

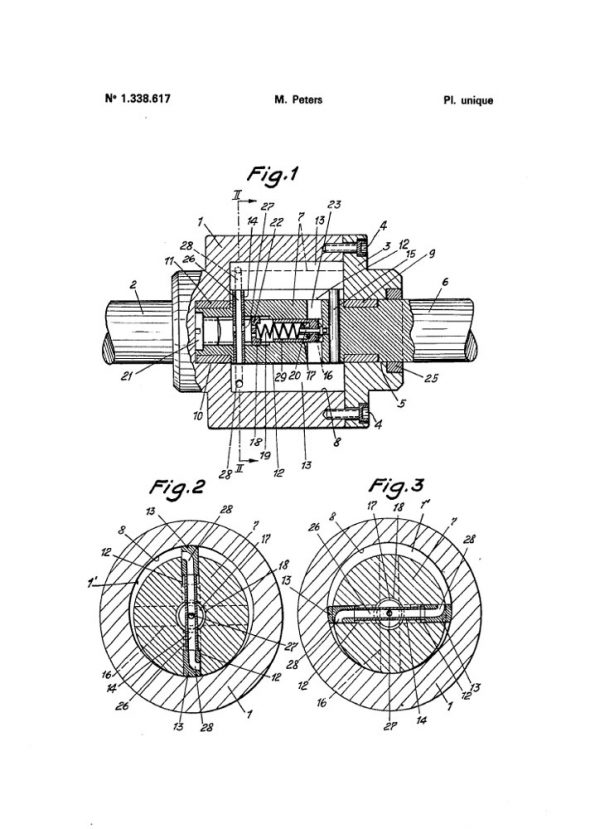

Waar conventionele flowmeters stagneren bij vervuilde vloeistoffen, gaat de 4e generatie flowmeter van PetersInvent verder. Wij hebben een baanbrekende constructie ontwikkeld waarbij een vrij roterend element (bal-technologie) de kern van de meting vormt. Dit combineert uiterste precisie met de robuustheid die nodig is voor het meten van vervuilde vloeistoffen.

Bekijk de technologie in actie:

Ontdek in enkele minuten hoe PetersInvent de markt voor vloeistofmeting transformeert. Video YouTube (2:22 min).

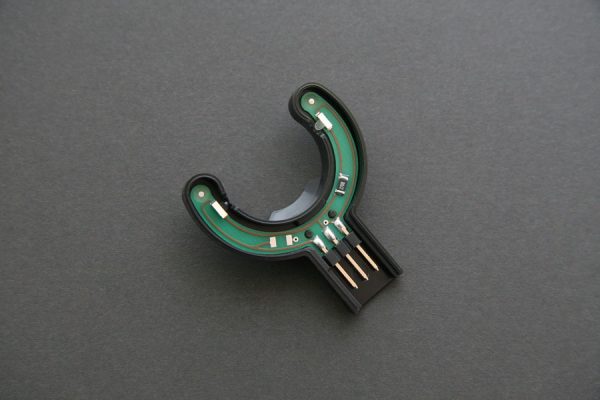

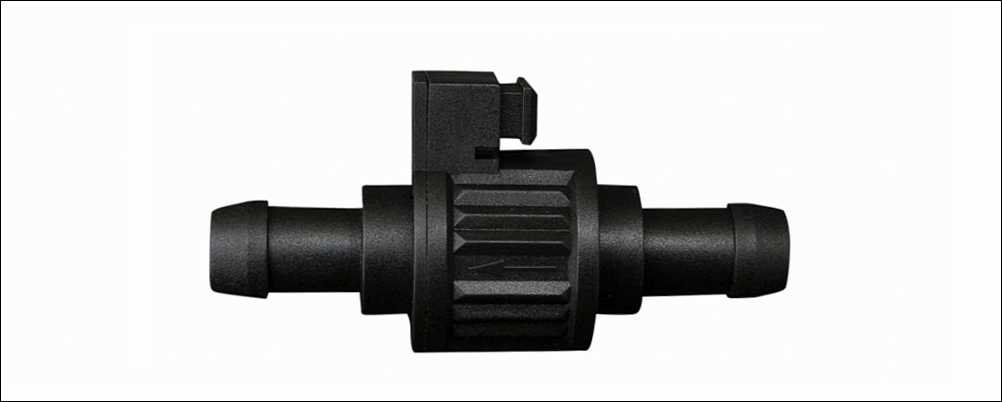

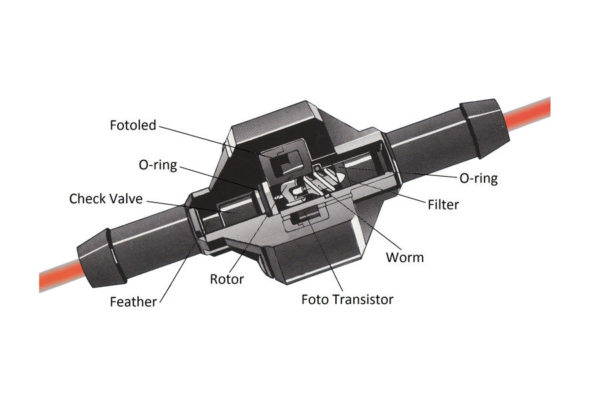

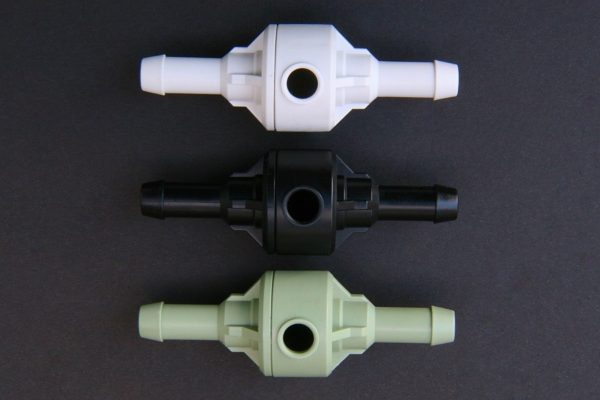

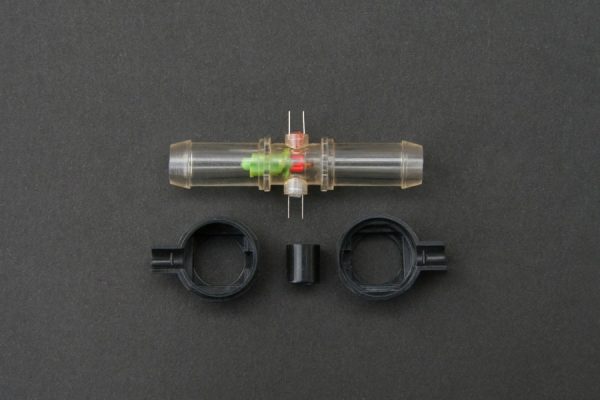

Nieuw: De 8e generatie flowmeter Rotor-serie – Ongeëvenaarde nauwkeurigheid

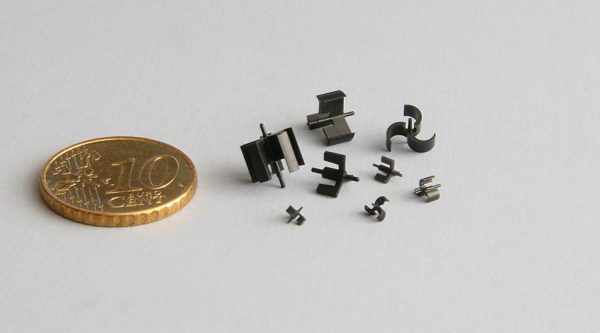

De inmiddels 30 jaar oude 2e generatie flowmeter heeft een metamorfose ondergaan. Dankzij innovatieve toepassingen is voor het eerst volledige massaproductie mogelijk, waarbij er aan de montagetechniek geen mensenhand meer te pas komt. Deze 8e generatie flowmeter is het resultaat van 25 jaar expertise op dit specialistische gebied en is zo efficiënt ontworpen dat deze tegen een zeer scherp ‘low budget’ tarief geproduceerd kan worden, zonder in te leveren op kwaliteit. Sterker nog: de nauwkeurigheid is door de nieuwste ontwikkelingen zelfs verbeterd.

Ook de elektronica is volledig vernieuwd en wordt nu volledig geautomatiseerd en kostenefficiënt samengesteld. Onze eerste drie generaties rotor-flowmeters zijn al ruim 30 jaar de benchmark voor het doseren van hoogwaardige, schone vloeistoffen. Dankzij een ultralichte rotor van slechts 0,0047 gram bereiken we een meetnauwkeurigheid die uniek is in de markt.

Bekijk de technologie in actie: Video YouTube.

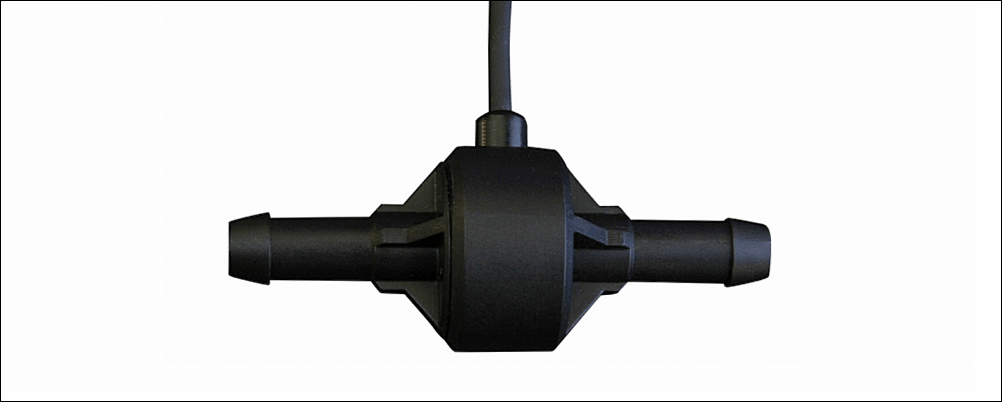

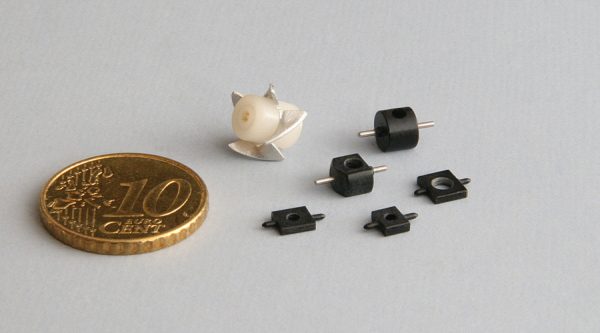

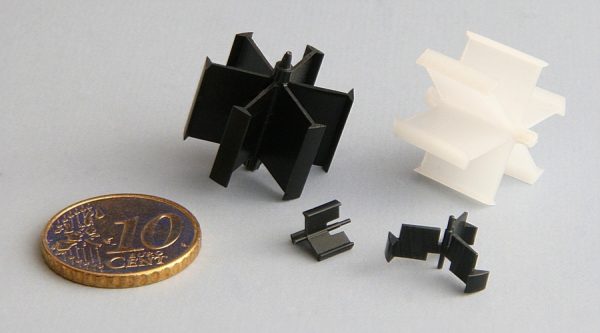

Nieuw: De 9e generatie Micrometers – Doseren met ongekende precisie

PetersInvent introduceert de 9e generatie Micrometers, specifiek ontwikkeld voor vloeistofdoseringen vanaf 0,1 ml. Deze uiterste nauwkeurigheid is cruciaal voor de farmaceutische, medische en chemische industrie. Waar elke druppel telt.

Technische perfectie in elk detail:

Milliseconde-injectie: Een geavanceerd systeem voor razendsnelle en uiterst nauwkeurige injecties.

Revolutionaire rotor: Dankzij een wrijvingsloze rotor van slechts 0,0047 gram worden doorstromingen vanaf 6 ml/min feilloos gemeten.

Maximale flexibiliteit: Keuze uit drie modellen met verschillende meetbereiken en weerstandskarakteristieken voor elke specifieke toepassing.

Betrouwbaar: Gegarandeerde precisie, zelfs bij pulserende of onregelmatige vloeistofstromen.

Bekijk de technologie in actie: Video YouTube.

Een totaaloplossing voor elk inzetgebied

Gezamenlijk bestrijken deze drie type flowmeters een zeer groot inzetgebied. Door de stap naar volledige machinale assemblage combineert PetersInvent revolutionaire techniek met de voordelen van massaproductie. Het resultaat? Hoogwaardige doseerprecisie tegen een ongekend laag prijsniveau.

PetersInvent: De nieuwe standaard in doseringstechnologie.