POSSIBILITIES 4G

De SF4 14G: Onverwoestbare flowmeter die presteert waar anderen stagneren

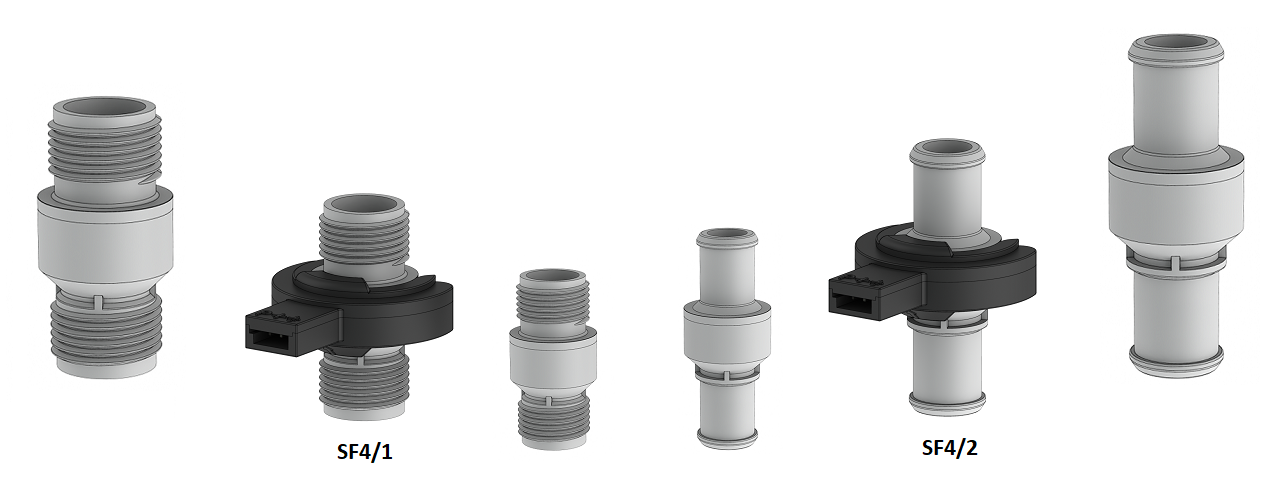

Different Sizes

Different Sizes

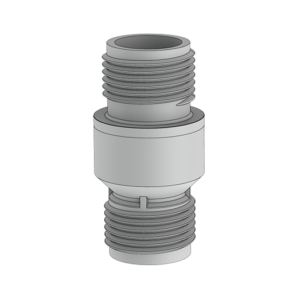

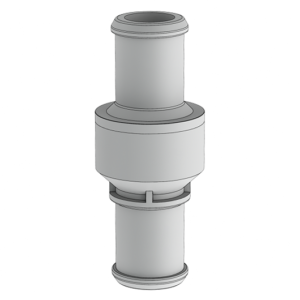

The design of this new Flow Meter makes it possible to scale the casing in different diameters. The diameter of the flow meter determines the accuracy in a certain area. The SF4/1 base version has a passage of 12mm/0,47 inch which results in an accuracy of less than 2% in the range of 1 to 18Lpm/0,26 to 4,75gpm. By scaling the diameter of the casing it is possible to achieve the same accuracy in a range of 0.1 to 120Lpm/0,026 to 31,7 gpm.

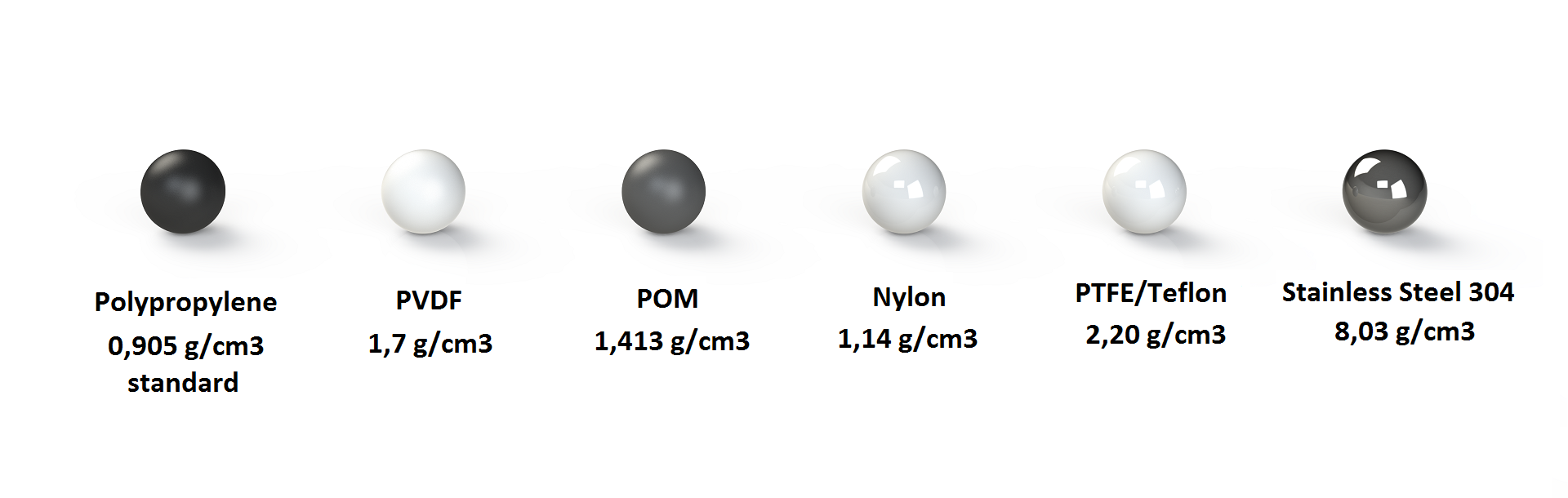

Specific Gravity

Specific Gravity

This new Flow Meter has been developed on the basis of a ball. It is possible to adjust the density of the ball to the density of the fluid to achieve the best results. For instance a thicker fluid than water will require a ball with higher density to get the most accurate reading. Because of this construction it should be possible to dose thick fluids, like paint or gear oil SAE150 with Viscosity 43.000 CentiStokes.

The architecture of the flow meter is independent of the used ball.

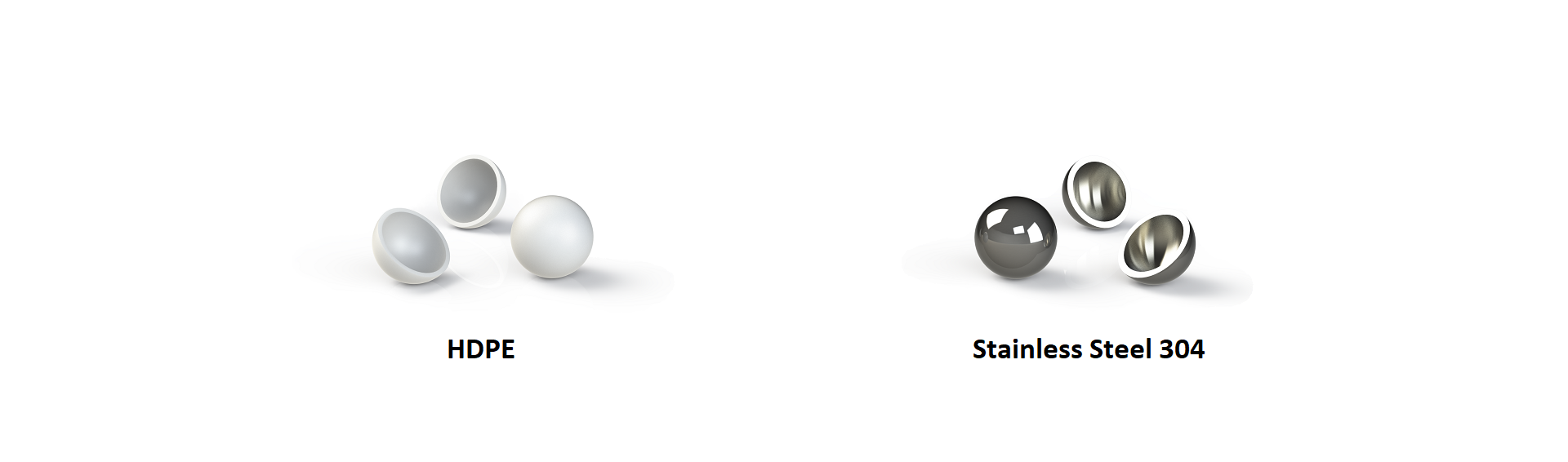

Hollow Balls

Hollow Balls

The hollow balls are suitable for special goals. The plastic hollow ball is light in weight and can be used to measure the flow of different gases. The metal hollow ball can be used with fluids where infrared technology is not possible, f.i. milk or paint. Detection of this ball is done by an Inductive Proximity Sensor, which can detect metal. This sensor is also capable of detecting a massive ball, but in practise the weight of this ball is too heavy for most of the fluids to get an accurate reading.

Detection Systems

Detection Systems

The detection of the ball can be done in three different ways:

- Infrared System: based on infrared light icw a photocell

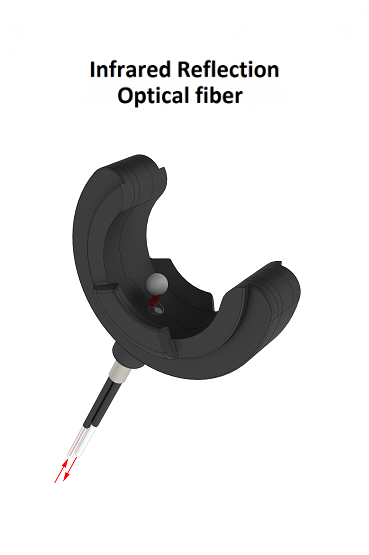

- Infrared Reflection: based on fiberglass

- Inductive Proximity Sensor: based on metal detection

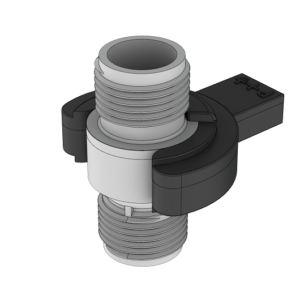

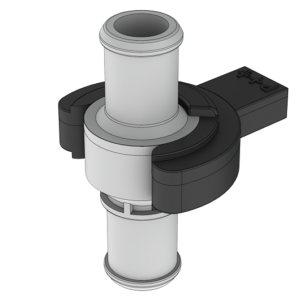

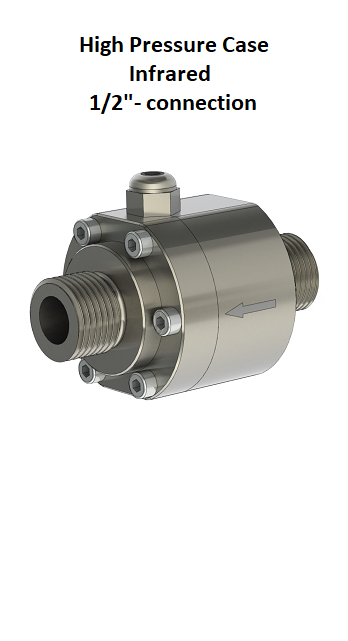

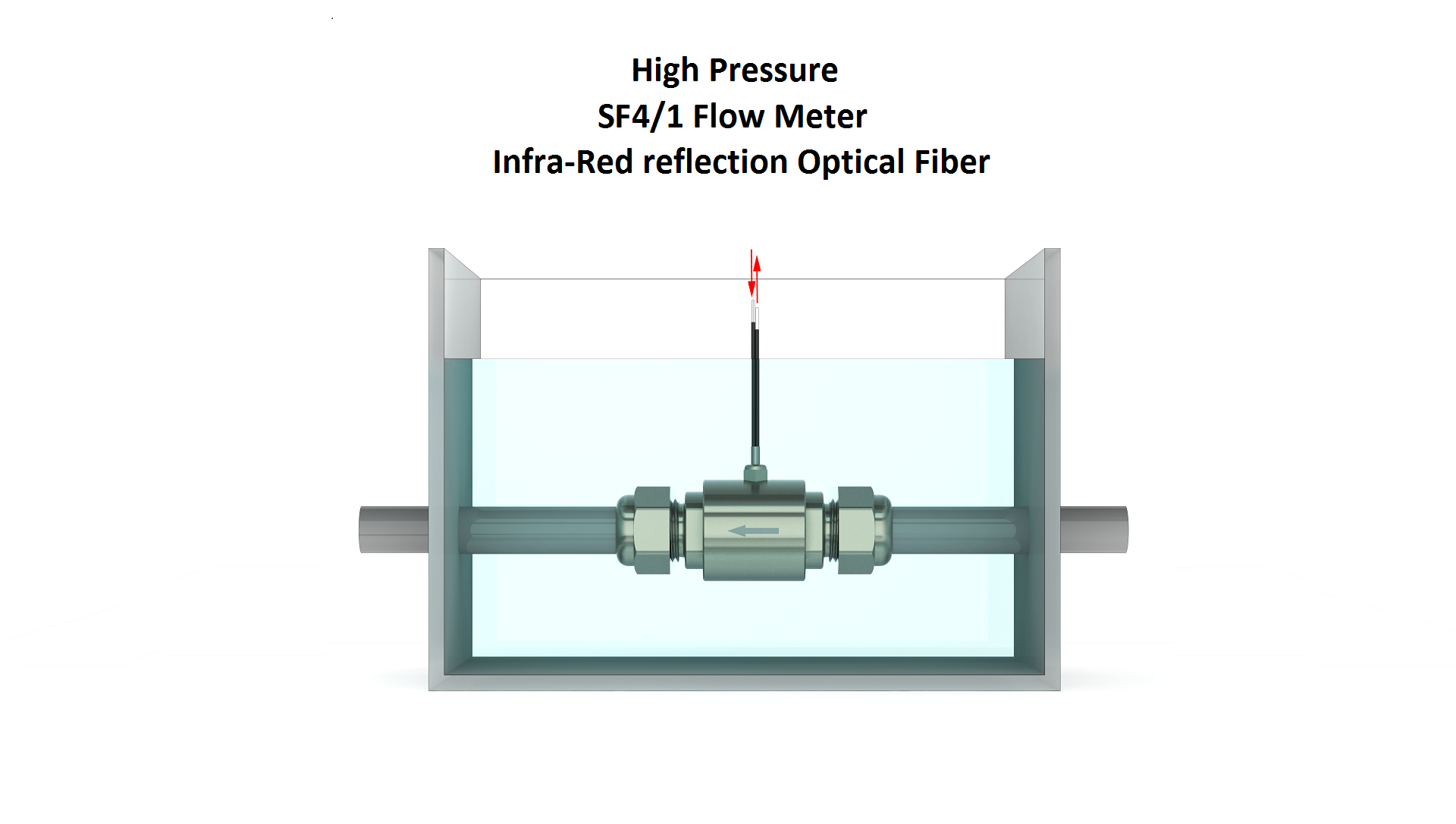

High Pressure Flow Meter

High Pressure Casing

PetersInvent High Pressure Casings can be used in a wide range of production processes. When using the stainless steel casing a pressure of 100 bar (and above) is possible to work with. The pressure casings are in development and research is ongoing to determine the maximal pressure for these casings.

The stainless steel casing is delivered i.c.w. the SF4/1 base version flow meter only. Two different systems are available:

- Infrared System. This solution is available with 1/2” – 3/8” connection.

- Infrared Reflection System. Available with 1/2” connection only.

The choice of the system determines the outside diameter of the pressure casing due to the electronic that is in. The infrared system is bigger in size w.r.t the fiberglass casing.

Tri-Clamp Connector

Tri-Clamp Connector

Tri-Clamp Connectors are simple, safe and sterilisable.

In applications requiring absolute cleanliness and reliability such as the pharmaceuticals industry, sterilisable Tri-Clamp threaded connectors are essential. The Tri-Clamp connector can be combined with various connectors and is easy to use:

- The seal is made by pressing two flange-like connectors together and secured with a locking clip

- A sealing-ring between the connecting sections creates an effective and reliable seal

- The resulting connection is form-fit and smooth

- A wing nut on the locking clip makes it easy to quickly open and close the connection at any time

More information about the Flow Meter can be found in the Flow Meter specifications.

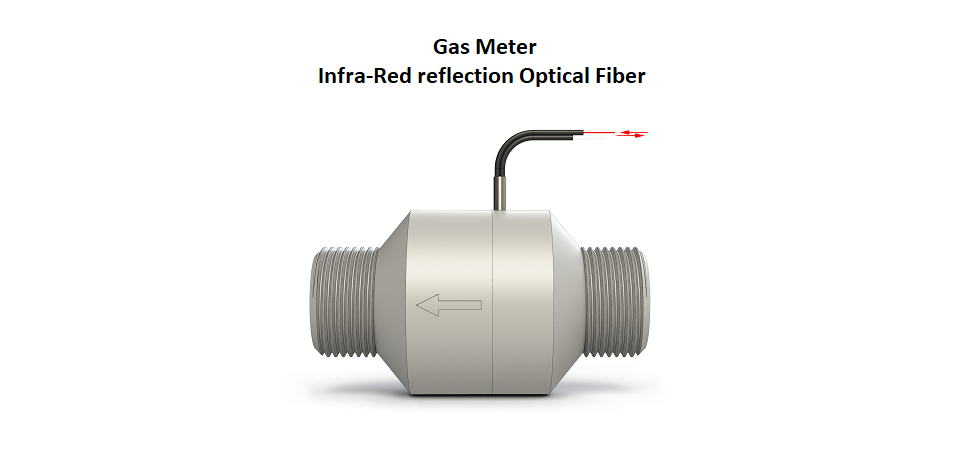

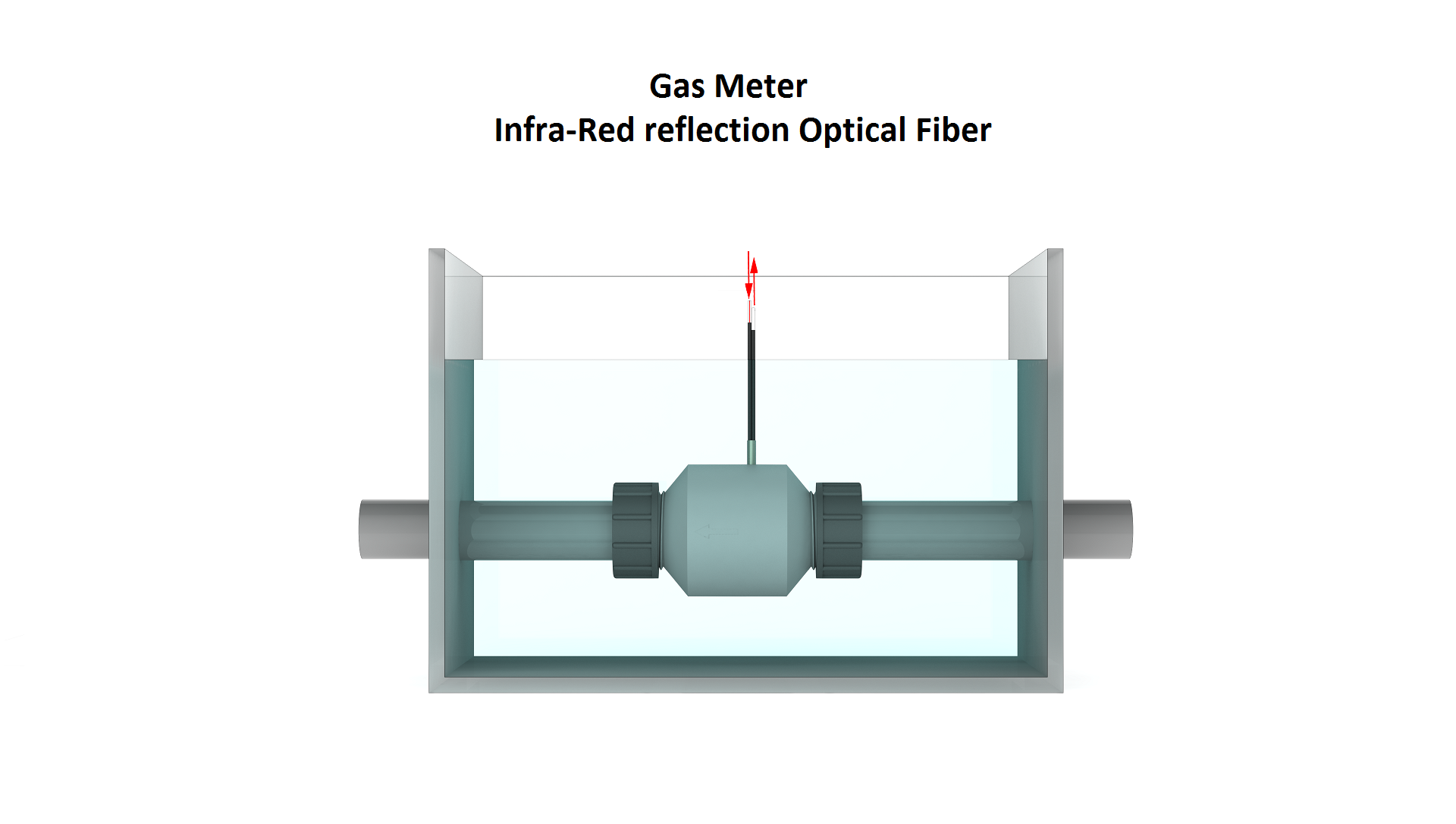

Gas Meter

Gas Meter

The main goal of this gas meter is to minimize the resistance of the gas in the meter itself to achieve the best accuracy.

This gas meter is equipped with a sensitive light-weight rotor which reacts to minimal gas flow. There is 30 years of knowledge and experience in this new meter. Refer to our last three generations patented flow meters.

The gas meter is composed of only a few plastic parts and a rotor. The fiberglass reflection system detects the movement of the rotor. There is no electricity in this flow meter, making it is safe to use with hazardous flammable gases.

The design of this gas meter is already adapted for use with a metal casing to serve high pressure applications.

Mechanical ventilator

This gas meter would be very suitable for putting together an inexpensive, comprehensible, reliable respirator for the fight against Covid-19.

A compact ventilation unit that can be used to save human lives anywhere in the world.

By using two gas meters for mechanical in and out ventilation, it is possible to produce a compact, high-quality ventilator for less than 500 euro. This concept allows for a different composition of components. By using these specially developed gas meters, less high demands can be placed on the air pump. The gas meters become the determining factor for the ventilation equipment. The gas meters significantly reduce the composition costs of a respirator.

The newly developed gas meter is a high-tech, accurate measuring instrument. Very suitable for measuring variable air flows such as seen in ventilation. It is capable of accurately measuring and dosing gas flows.

Our gas meter consists of only 3 plastic parts. All proportions in the gas meter are attuned to each other in such a way that the variable airflow can be measured/detected as accurately as possible.

This gas meter is capable of measuring even the smallest of airflows. Even a minimal amount of air displacement sets the specially designed lightweight rotor into motion. This feat required a high level of technical development of the rotor to pull off. The wings interrupt a signal that is then converted into pulses. Calculating the amount of pulses and the time past allows for complete control over the entire ventilation system. The electronics control the pump and the control valves to achieve the ventilation process as desired by medical specialists. Mounting this gas meter between the ventilation hoses (in and out), makes full control over the ventilation possible. To keep the total cost for the gas meter including electronics low, there are solutions available that make the rotor readable based on an infrared system.

In the past, we worked on this development purely for ourselves and at the time it challenged us to develop an accurate gas meter for just a few euros. We succeeded and our base design/prototype remained untouched.

We have never met people with the technical skills needed to make this technique ready for production. Designing a respirator with fully reliable control over ventilation should be possible for a few hundred euros at most. A team with sufficient technical skills in different disciplines that is able to work well together is essential to achieve success.

At PetersInvent, we have never looked for companies interested in this new gas meter technology. Finding the right companies is not our specialty. We just want to innovate.

In innovation, everything revolves around the right technical team and complete confidence to be and remain successful.

Unfortunately, details of the composition of the Gas Meter cannot be revealed because the product is not yet protected. This knowledge is registered. Where new developments can be registered safely. This legally recognized system can be used as legal evidence.

If no one comes up with it, it will never exist.

Technical information about the Gas Meter can be found in Gas Meter Specifications.

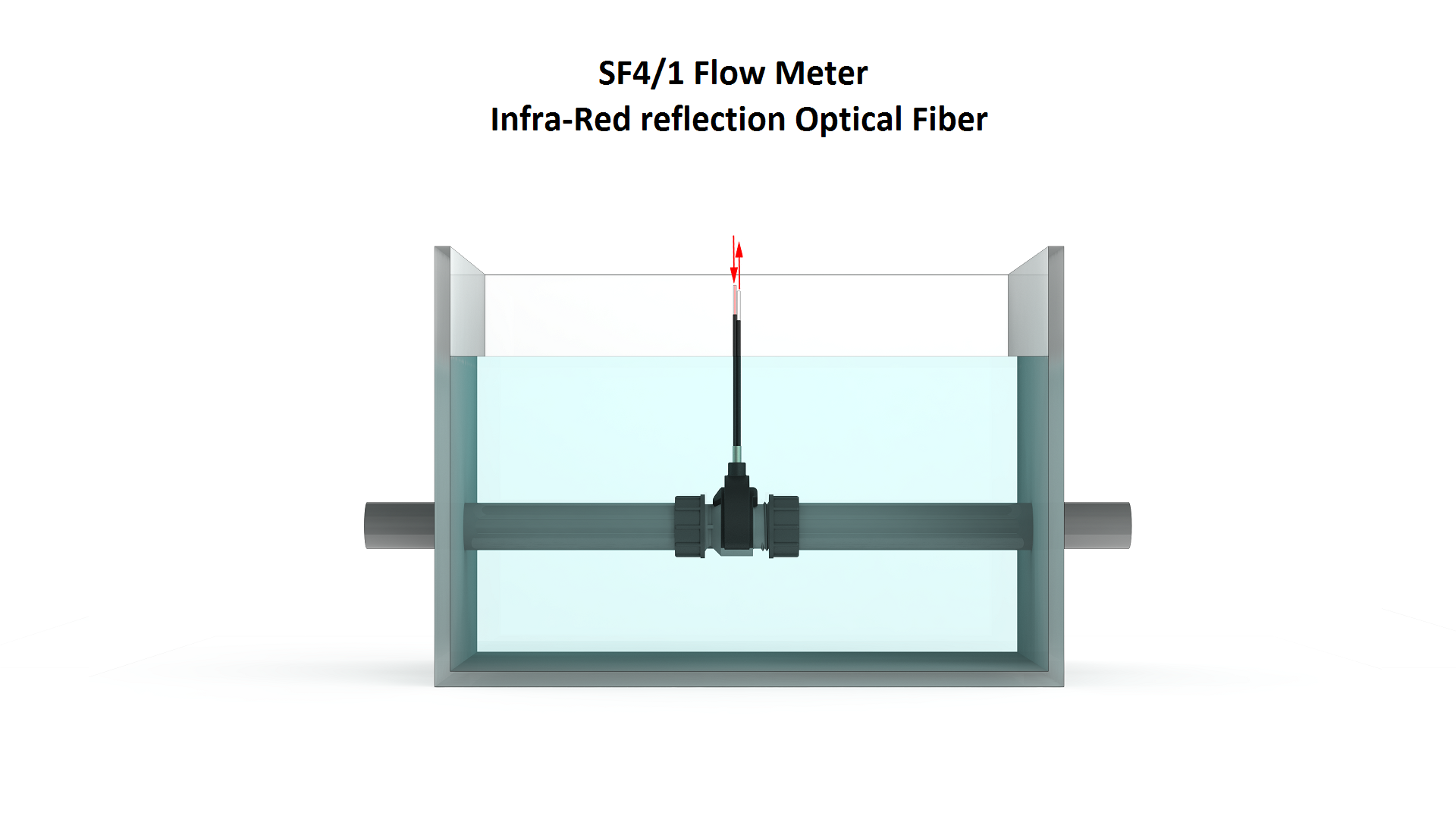

Underwater Measurement

More information can be found in SF4/1 Flow Meter Underwater measurement.

More information can be found in SF4/1 Flow Meter High Pressure Casing for Underwater measurement.

More information can be found in Gas meter Underwater measurement.